Composite Performers

COMPOSITE PERFORMERS

Job Specification

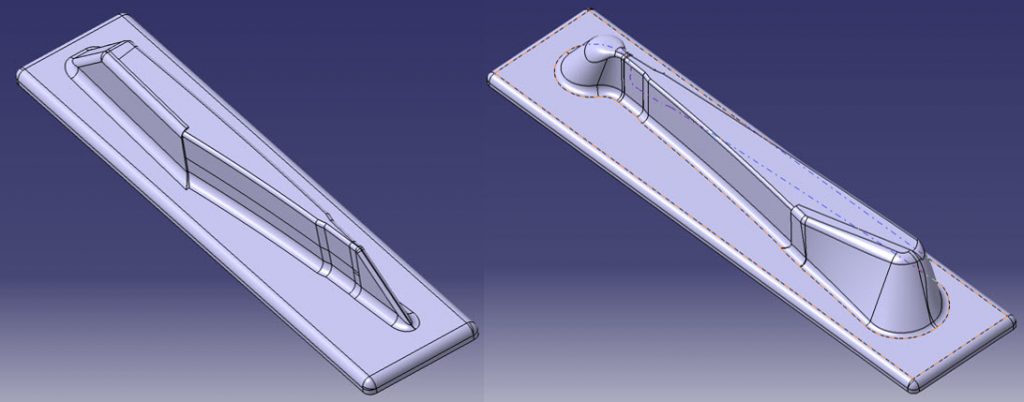

Our customer required a tool that would be suitable to produce preforms of limited amount of parts.

In the preforming process, several individual layers of fibre form material are cut and draped in one, two or three dimensions in the approximate shape, contour and thickness desired in the finished composite part. Heat and pressure is then applied to give the parts structure.

Near-net-shape preforming significantly reduces the consumption of the valuable raw material creating performers.

FDM recommended printing the composite performers in FDM material Ultem 9085

- This material is able to withstand the temperatures and pressures applied during the forming process.

- This saved the customer metallic tooling costs of around £5000

- Tool manufacture lead time meant the tools were ready in days not weeks