Developing Bespoke Aerospace Tooling with 3D Printing

DEVELOPING BESPOKE AEROSPACE TOOLING WITH 3D PRINTING

Problem

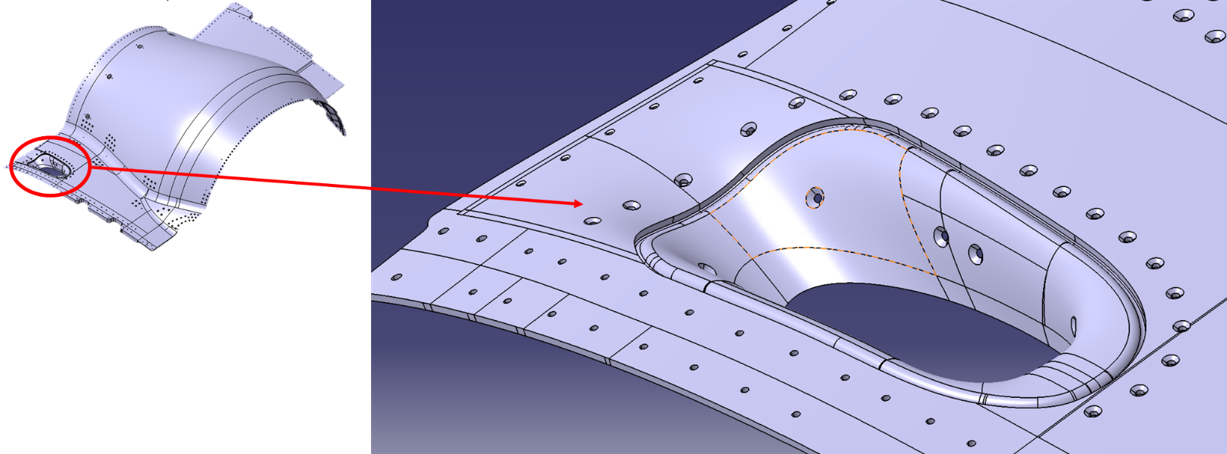

Drilling and countersinking of the Pre-cooler Scoop to the IFS panel. The standard process is to countersink a hole using a “Vanmar Micro-stop Cutter Cage”, this tool sits flat on the surface of the component when being used. However, the Pre-cooler Scoop has a complex 3D curved surface so the Vanmar would not sit flat, thus causing a problem for the operator and subsequent concession costs.

Solution

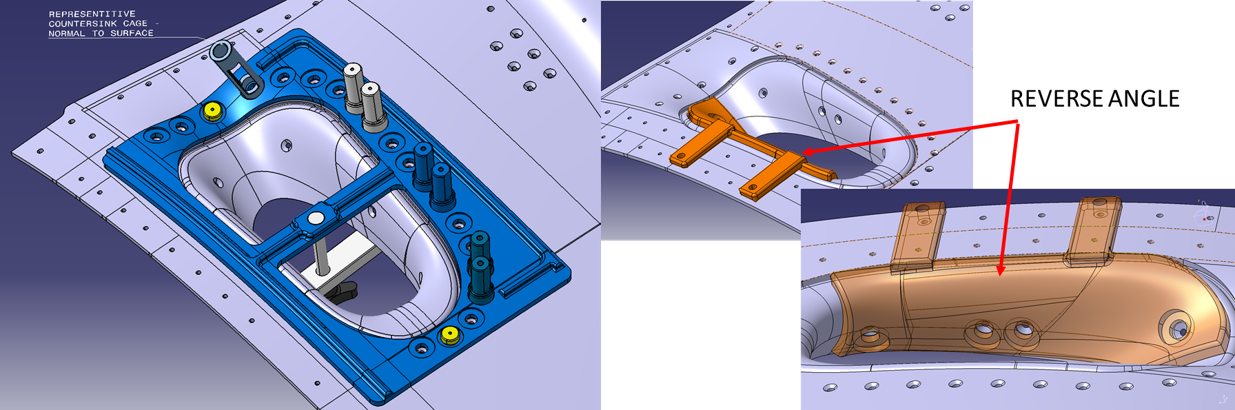

3D Printed tools to match the profile of the air-scoop with offset surfaces enabling repeatable correct position of drill motors and the Vanmar cage in line with the relevant vector. Customer saw production savings and rework savings.